Wasson’s Tedlar Bag Auto-samplers allow for automated, unattended sampling of tedlar bags (and/or cylinders) to assist busy laboratories increase repeatability, reproducibility, and sample throughput while minimizing operator variance.

Labor is needed to swap between unknown samples between subsequent runs of unknown samples.

Tedlar bags are commonly used to collect samples containing hydrogen and helium, but these compounds are able to permeate Tedlar so these samples should be analyzed as soon as possible after collection to mitigate any losses due to permeation. Depending on the analytes of interest and method compliance, this timeframe is generally between 24 and 72 hours. Lack of available manpower can delay analysis.

Wasson-ECE’s TAS301 Tedlar Bag Auto-sampler is designed to help busy laboratories increase throughput and reduce manpower requirements through unattended, automated sampling of up to 16 samples.

Reproducibility

Operator variance reduces reproducibility. This laboratory device eliminates this variance and increase reproducibility.

For customers performing analysis of components found in atmospheric air (i.e oxygen, nitrogen), Wasson ECE offers two Tedlar Auto-sampler models with optional external pumps that provide lower ultimate vacuums (than the internal pumps supplied with the base system) to help minimize sample contamination from residual air in the Tedlar Bag Auto-sampler tubing.

Available in Multiple Sizes

Wasson ECE offers both a full size 16 position Tedlar Auto-sampler and a mini, 6 position Tedlar Auto-sampler to minimize the benchtop footprint.

Ability to sample Tedlar Bags and/or Cylinders

To avoid having to manually inject cylinder samples and/or utilize a secondary device, Wasson’s Tedlar Auto-samplers are adaptable to automate sampling of both Tedlar bags and/or cylinders on the same run. Optional stop flow and pump bypass valve are used for pressurized cylinders.

Wasson’s Tedlar Bag Auto-samplers allow for automated, unattended sampling of up to 16 Tedlar bags (a popular medium for collecting air samples as they are light, portable, and inexpensive) and/or sample cylinders to assist busy laboratories increase sample throughput, repeatability, reproducibility, while minimizing manpower requirements and operator variance.

An on-board diaphragm vacuum pump pulls samples from the Tedlar® bags to the gas sampling valve on Agilent Gas Chromatographs (GC) for analysis. Sampling is controlled by the GC software sequence editor; no additional software is required.

Labor is needed to swap between unknown samples between subsequent runs of unknown samples.

Tedlar bags are commonly used to collect samples containing hydrogen and helium, but these compounds are able to permeate Tedlar so these samples should be analyzed as soon as possible after collection to mitigate any losses due to permeation. Depending on the analytes of interest and method compliance, this timeframe is generally between 24 and 72 hours. Lack of available manpower can delay analysis.

Wasson-ECE’s TAS301 Tedlar Bag Auto-sampler is designed to help busy laboratories increase throughput and reduce manpower requirements through unattended, automated sampling of up to 16 samples.

Reproducibility

Operator variance reduces reproducibility. This laboratory device eliminates this variance and increase reproducibility.

For customers performing analysis of components found in atmospheric air (i.e oxygen, nitrogen), Wasson ECE offers two Tedlar Auto-sampler models with optional external pumps that provide lower ultimate vacuums (than the internal pumps supplied with the base system) to help minimize sample contamination from residual air in the Tedlar Bag Auto-sampler tubing.

Available in Multiple Sizes

Wasson ECE offers both a full size 16 position Tedlar Auto-sampler and a mini, 6 position Tedlar Auto-sampler to minimize the benchtop footprint.

Ability to sample Tedlar Bags and/or Cylinders

To avoid having to manually inject cylinder samples and/or utilize a secondary device, Wasson’s Tedlar Auto-samplers are adaptable to automate sampling of both Tedlar bags and/or cylinders on the same run. Optional stop flow and pump bypass valve are used for pressurized cylinders.

Wasson’s Tedlar Bag Auto-samplers allow for automated, unattended sampling of up to 16 Tedlar bags (a popular medium for collecting air samples as they are light, portable, and inexpensive) and/or sample cylinders to assist busy laboratories increase sample throughput, repeatability, reproducibility, while minimizing manpower requirements and operator variance.

An on-board diaphragm vacuum pump pulls samples from the Tedlar® bags to the gas sampling valve on Agilent Gas Chromatographs (GC) for analysis. Sampling is controlled by the GC software sequence editor; no additional software is required.

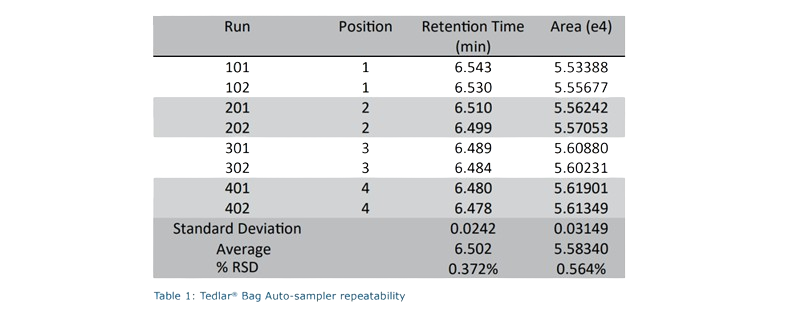

Tedlar® Bag Auto-sampler repeatability was tested using an Agilent 7890A configured with a thermal conductivity detector (TCD). Four Tedlar® bags were loaded with house nitrogen and connected to sample positions 1-4. Prior to opening the bag valves, a pre-vacuum method was run to pull vacuum on the samples line to remove any entrained air in the interconnect tubing. The bag valves were then opened and the sampling sequence was run. The area repeatability results over eight runs was 0.564 %RSD, as shown below in Table 1.

Features:

- Allows for automated, unattended sampling of up to 6 tedlar bags (and/or cylinders)

- Compatible with Agilent 8890, 8860, 8850, 7890, 6890 and micro 990 models as well as other vendor GC models

- Requires gas sampling valve on GC (or Wasson can add to the Auto-sampler)

- Controlled by GC through OpenLAB Chemstation, EZ Chrom, Masshunter (or alternate) software

Includes:

- Valco 6-position stop flow multi-position valve

- 1/4” bulkhead connections (right side of auto-sampler)

- Two solenoid valves

- Valve controller

- Internal diaphragm vacuum pump

Optional Items:

- Optional gas sampling valve

- Optional external pump available

- Optional stop flow and pump bypass valve for pressurized cylinders

- Optional passivated (sulfi) lines

Dimensions: 13.4” H x 14.5” W x 19.8” D (34 cm H x 36.8 cm W x 50.3 cm D)

Weight: 35 lbs (15.87 kg)

Minimum required electrical supply: 115/220V

Features:

- Allows for automated, unattended sampling of up to 16 tedlar bags (and/or cylinders)

- Compatible with Agilent 8890, 8860, 8850, 7890, 6890 and micro 990 models as well as other vendor GC models.

- Requires gas sampling valve on GC (or Wasson can add to the Auto-sampler)

- Controlled by GC through OpenLAB Chemstation, EZ Chrom, Masshunter (or alternate) software

Includes:

- Valco 16-position stop flow multi-position valve

- 1/4” bulkhead connections (right side of auto-sampler)

- Two solenoid valves

- Valve controller

- Internal diaphragm vacuum pump

Optional Items:

- Optional gas sampling valve

- Optional external pump available

- Optional stop flow and pump bypass valve for pressurized cylinders

- Optional passivated (sulfi) lines

Dimensions: 31”H x 24”W x 12”D (78.7 cm H x 61 cm W x 30.5 cm D)

Weight: 41 lbs (18.6 kg)

Minimum required electrical supply: 115/220V

Wasson-ECE Instrumentation

101 Rome Ct., Fort Collins, Colorado USA 80524

Phone: +1 (970) 221-9179

Fax: +1 (970) 221-9364

© 2026. All Rights Reserved.

When you can't afford to be wrong. TM